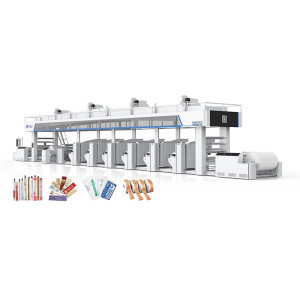

Paper cup, paper bag, carton pre-printing, food packaging, tobacco and alcohol packaging, pharmaceutical packaging, daily

necessities, non-woven fabric, plastic film, industrial products, and other flexible packaging materials

Paper cup, paper bag, carton pre-printing, food packaging, tobacco and alcohol packaging, pharmaceutical packaging, daily

necessities, non-woven fabric, plastic film, industrial products, and other flexible packaging materials

1. Drive mode: servo system drive

2. Color printing method: automatic computer overprinting device

3. Detection system: color printing effect monitoring system

4. Advance and retreat system:

plate roller and anilo roller are electrically controlled, which can achieve fast advance and retreat

5. Inking mode: fullyenclosed scraper inking system

6. Tension control: multi-section tension control, floating roller detection, automatic control

7.Applicable ink: water-based ink, solvent ink and UV ink

8. Drying device: extended drying system is adopted for color group drying

9. Dry heat source: electricity, steam, thermal oil, natural gas, etc

10. Discharge correction: adopt high precision deviation correction device

11. Feeding control: automatic control with pneumatic brake

12. Rewind control: controlled by frequency

conversion motor

|

Model |

KSJP-ST-6850 |

KSJP-ST-61050 |

KSJP-ST-61350 |

KSJP-S6-61650 |

|

|

Max Material Width |

800mm |

1000mm |

1300mm |

1600mm |

|

|

Max Printing width |

780mm |

980mm |

1280mm |

1580mm |

|

|

Printing length |

320-1200mm |

320-1200mm |

320-1200mm |

320-1200mm |

|

|

Printing color |

1-12 color |

||||

|

Mechanical speed |

20-220m/min |

||||

|

Printing speed |

20-200m/min |

||||

|

Printing unit Composition |

Ceramic anilox roller, Chamber doctor blade, Ink pump, Printing cylinder, Pressure roller |

||||

|

Voltage |

3p 380v 50hz |

||||

|

Weight |

25000kg |

30000kg |

35000kg |

40000kg |

|

|

Dimension |

20*2.1*1.5m |

20*2.3*1.5m |

20*2.5*1.5m |

20*2.7*1.5m |

|

|

Optional devices |

1..Corona treatment 2.Automatic non-stop unwind&rewind1.Online device |

||||

Main features:

1. The whole machine is controlled by PC and servo motor control system, and equipped with remote service device, which is convenient to solve problems quickly;

2. The color registration adopts automatic computer automatic color registration and HD color still picture monitoring, which is convenient for the observation of printing quality;

3. It is applicable to the duplex type of paper unwinding without core, and it is applicable to the automatic unwinding position of + 6 inches; Full automatic roll changing without shutdown, material receiving speed is 260m / min.

1.Function: multi-color continuous fine printing, at the same time to achieve reverse gluing

2.Features: accurate color matching, stable operation, model customization

3.Application: mask packaging, pharmaceutical paper packaging, food paper packaging

Main features:

1. The whole machine is controlled by PC and servo motor control system; And equipped with remote service device to facilitate and quickly solve problems;

2. The color registration adopts automatic computer automatic color registration and HD color still picture monitoring, which is convenient for the observation of printing quality;

3. Unwinding adopts shaftless hydraulic automatic feeding, which is suitable for 3 + 6 inch paper core;